The little cello has been so much fun – I rarely get the big one out anymore. The guitar tuners worked OK, but I wasn’t really happy with the way they fit on the pegbox, and I didn’t like the look of them, especially as I have grown more attached to the cello! Since I knew this cello was a keeper, I was willing to spend a little more and get some nice pegs.

My son has Perfection Pegs on his violin and they work well. I thought I would get some for the cello, until I discovered the Wittner Finetune peg. These pegs have gears in the knob, rather than in the shaft. The gear ratio (8.5:1) is double that of the Perfection Pegs so fine tuning is easier. The pegs are made of plastic, but the molding quality and finish are very fine, so they don’t look like plastic.

My son has Perfection Pegs on his violin and they work well. I thought I would get some for the cello, until I discovered the Wittner Finetune peg. These pegs have gears in the knob, rather than in the shaft. The gear ratio (8.5:1) is double that of the Perfection Pegs so fine tuning is easier. The pegs are made of plastic, but the molding quality and finish are very fine, so they don’t look like plastic.

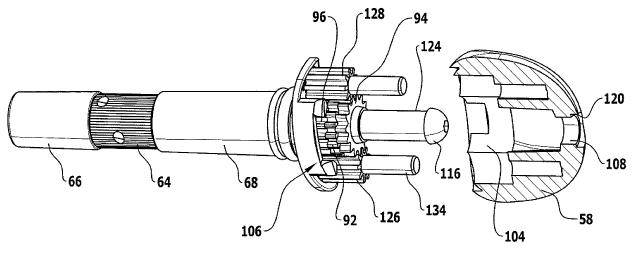

These pegs use a simple, but ingenious mechanism. I couldn’t figure out how they worked until I found the patent and Google translated it from German. The gearbox is a self-locking design due to the use of two gears of slightly different tooth count (labeled 92 and 94 in the drawing). The planet gears engage the two gears simultaneously and, as they rotate around them, the two gears slowly rotate relative to each other. The tension of the string cannot move the gears, but the knob turns them freely. Perfection Pegs press in to lock using a friction brake concept that isn’t needed with the Finetune pegs.

These pegs use a simple, but ingenious mechanism. I couldn’t figure out how they worked until I found the patent and Google translated it from German. The gearbox is a self-locking design due to the use of two gears of slightly different tooth count (labeled 92 and 94 in the drawing). The planet gears engage the two gears simultaneously and, as they rotate around them, the two gears slowly rotate relative to each other. The tension of the string cannot move the gears, but the knob turns them freely. Perfection Pegs press in to lock using a friction brake concept that isn’t needed with the Finetune pegs.

I bought a set of the larger (8.6mm) violin pegs for $60 and they fit my little cello perfectly. They press tightly into the normal peg holes and don’t require any cement. The G peg doesn’t stick out far enough to bother my neck. The cello stays in tune very well. The pegs will move if you bump them, but in normal handling they don’t budge.

I cut off and sanded smooth the extended ends of the pegs and I think they look great. I guess the visual appeal of the cello has become more important than I would have expected. Must be a subliminal association with the pleasure of making music!